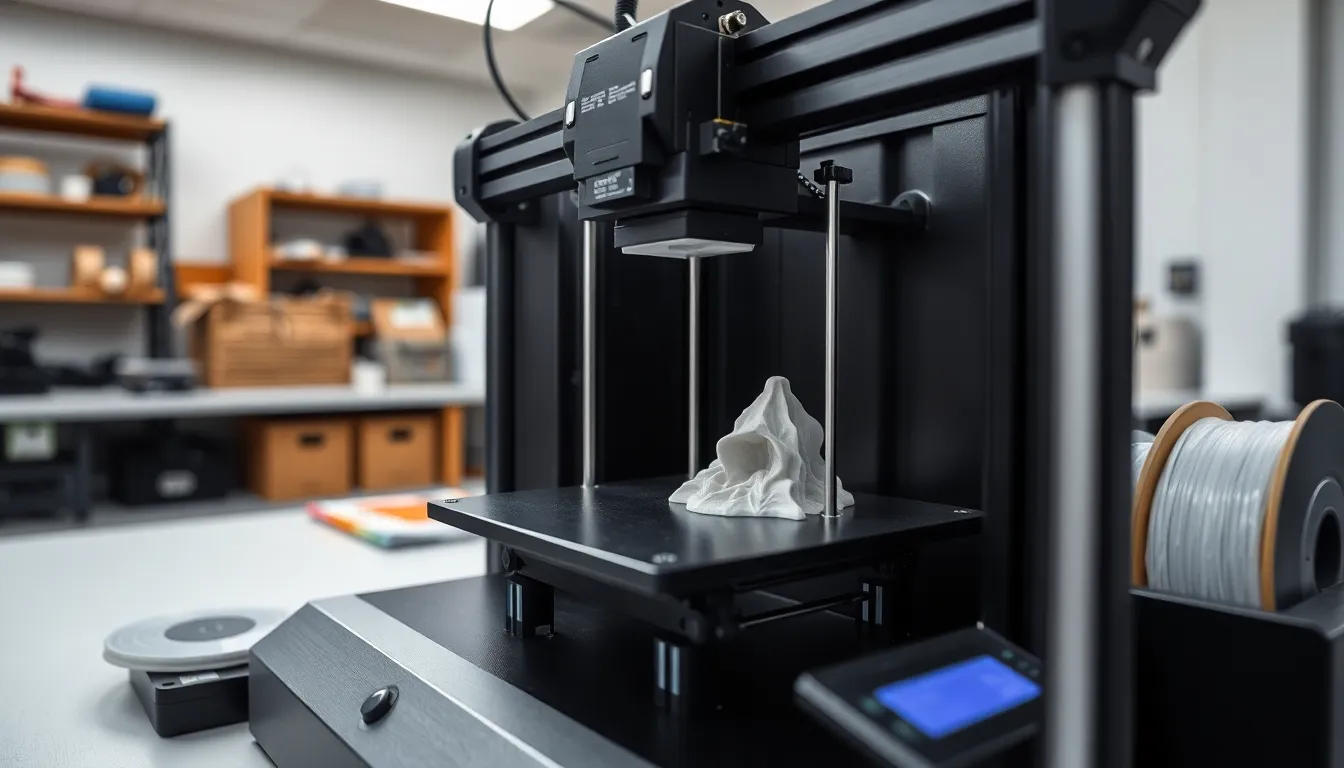

In the world of manufacturing and design, 3D printing has revolutionized how products are created. As technology advances, the focus on 3D print precision has become increasingly vital. Achieving high precision in 3D printing not only enhances the quality of finished products but also opens doors to innovative applications across various industries.

From aerospace to healthcare, the ability to produce intricate designs with exact specifications can dramatically improve functionality and performance. As businesses seek to leverage the benefits of 3D printing, understanding the factors that influence precision becomes essential. This article delves into the key aspects of 3D print precision, exploring techniques and best practices that can elevate production standards and drive success in this dynamic field.

Table of Contents

ToggleOverview of 3D Print Precision

3D print precision refers to the accuracy and detail achievable in 3D printed objects. High precision impacts critical factors like fit, finish, and functionality. It’s essential across industries including aerospace, healthcare, and automotive, where tolerances can be as tight as ±0.1 mm.

Several factors affect 3D print precision:

- Printer Calibration: Regular calibration of 3D printers ensures consistent performance and accuracy.

- Material Selection: Different materials, such as PLA, ABS, or nylon, exhibit unique properties that influence precision.

- Layer Height: A lower layer height enhances detail but increases print time, while a higher layer height reduces print time but may sacrifice detail.

- Print Speed: Slower print speeds often lead to better accuracy, as the extruder has time to accurately place material.

- Environmental Conditions: Temperature and humidity can affect material behavior and precision; stable environments yield better results.

Employing techniques to enhance precision can optimize 3D printing outcomes. These techniques encompass:

- Adaptive Slicing: Manipulating layer height throughout the print enhances detail in complex areas while maintaining efficiency.

- Support Structures: Utilizing proper support structures minimizes material deformation during printing.

- Post-Processing: Methods like sanding and smoothing can refine the final product, achieving desired specifications.

Understanding these elements is vital for those aiming to improve product quality through 3D printing technology.

Factors Influencing 3D Print Precision

Achieving high precision in 3D printing hinges on various factors that significantly affect the final output. Key contributors include material selection, printer technology, and calibration settings.

Material Selection

Material selection impacts print precision as different materials have unique properties. Heavier materials may lead to stability issues during layering, while lighter materials might not adhere well, affecting detail. Common materials include:

- PLA: Offers good detail and minimal warping, suitable for prototypes.

- ABS: Known for durability, but can warp if not managed correctly.

- PETG: Balances ease of printing and strength, reducing print defects.

Choosing the right material based on the required properties ensures optimal precision in diverse applications.

Printer Technology

Printer technology varies widely, influencing precision levels. Advanced technologies like SLA (Stereolithography) and SLS (Selective Laser Sintering) achieve finer details and better surface finishes. Different technologies include:

- FDM Printers: Generally less precise, suitable for rapid prototyping.

- SLA Printers: Offer high resolution, ideal for intricate designs.

- SLS Printers: Provide durability with excellent structural integrity.

Selecting an appropriate printer technology based on project requirements enhances print quality.

Calibration and Settings

Calibration and settings determine the accuracy of 3D prints. Properly calibrated printers produce more consistent results. Key settings affecting precision include:

- Layer Height: Smaller layer heights yield finer details but increase print time.

- Print Speed: Faster speeds can lead to imperfections, while slower speeds improve quality.

- Nozzle Temperature: Maintaining optimal temperature ensures better adhesion and layer bonding.

Regular calibration and tuning of printer settings are essential for maintaining high precision throughout the printing process.

Techniques to Improve 3D Print Precision

Enhancing 3D print precision requires a multi-faceted approach, including software optimization and effective post-processing methods.

Software Optimization

Software optimization plays a crucial role in achieving high precision in 3D printing. Slicing software must accurately convert 3D models into instructions that the printer understands. Adjusting settings such as layer height, print speed, and infill density can lead to improved results.

- Adaptive Slicing: Using adaptive slicing techniques adjusts layer heights based on model geometry, allowing finer detail in complex areas while maintaining faster speeds in simpler ones.

- Support Settings: Proper configuration of support structures prevents defects in overhangs and bridges, contributing to better surface finish and overall accuracy.

- Calibration Settings: Regular calibration of software settings ensures that the virtual model aligns with physical outputs. This includes checking printer axes, stepper motor settings, and extrusion rates.

Post-Processing Methods

Post-processing methods significantly enhance the perceived precision of 3D printed objects. After prints are completed, implementing specific techniques can improve aesthetics and functional characteristics.

- Sanding: Sanding surfaces smooths out any rough areas or imperfections, resulting in cleaner lines and improved tactile quality.

- Painting and Finishing: Applying paint or other finishes can hide layer lines and imperfections, creating a polished look suitable for display or final products.

- Annealing: For certain materials, annealing involves heating printed objects to relieve internal stresses, enhancing dimensional stability and durability.

- Trimming and Assembly: Careful trimming and assembly ensure tight fits and refined details, crucial for components requiring precision alignment.

Real-World Applications of 3D Print Precision

3D print precision significantly impacts various industries, enabling the development of intricate designs and components that meet strict performance requirements.

Aerospace Industry

3D printing in aerospace focuses on lightweight, high-strength parts, shortening production times and reducing waste. Precision allows for the creation of complex geometries, such as brackets and ducts, that enhance aerodynamics and fuel efficiency. Noteworthy examples include GE Aviation’s fuel nozzle, which showcases precision in performance and reduction in assembly time.

Healthcare Sector

In healthcare, 3D print precision is crucial for developing personalized implants and prosthetics. Surgeons rely on accurately printed models for preoperative planning, leading to improved surgical outcomes. For instance, custom-fit dental aligners illustrate how precision affects comfort and effectiveness, while patient-specific anatomical models aid in precise surgical interventions.

Automotive Industry

The automotive sector benefits from 3D print precision through rapid prototyping and custom part production. Precise components lead to better fitting, reduced assembly times, and enhanced vehicle performance. For example, manufacturers utilize precision printing for intricate engine components and tooling solutions, streamlining production processes and minimizing costs.

Consumer Goods

The consumer goods industry leverages 3D print precision for custom designs in jewelry, footwear, and home decor. High-resolution prints allow for unique, detailed designs that appeal to consumer preferences. Brands using precision printing provide tailored products, enhancing customer satisfaction and fostering brand loyalty.

Architecture and Construction

In architecture and construction, 3D printing enables the creation of scale models and intricate structural components. Precise models facilitate accurate presentations and client discussions, while detailed components contribute to innovative designs in construction projects. Notable projects include 3D-printed housing structures that demonstrate the potential of precision in reducing waste and construction time.

Each application of 3D print precision underscores its transformative potential across various sectors, driving advancements in design, efficiency, and functionality.

3D print precision is a game changer across multiple industries. As technology advances the demand for high-quality and accurate prints will only increase. Emphasizing precision not only enhances product quality but also opens doors to innovative applications that can transform manufacturing and design.

By understanding the factors that influence precision and implementing best practices, businesses can achieve remarkable results. Whether it’s in aerospace, healthcare, or consumer goods, the ability to produce intricate and functional designs sets companies apart in a competitive landscape. The future of 3D printing lies in its precision, driving efficiency and creativity to new heights.